Aotearoa's Original Craft Bean-to-Bar Chocolate

At Wellington Chocolate Factory, we dream of a better-tasting world, one that’s more equitable for our farmers and more delicious for our customers.

We craft ethical, bean-to-bar chocolate using the highest quality ingredients, sourced directly from our Pacific Island neighbours. By paying a premium for their cocoa, we aim to build a more sustainable future, ensuring better livelihoods for farming communities and a stronger, more resilient cocoa industry across the region.

View the Pasifika Collection for our single origin bars that showcase the quality of Pacific cocoa and highlight the dedication of our producers

Our Ethical Sourcing

Ethical sourcing is in our DNA

Since day one we've been committed to sourcing the highest quality cocoa in the world and paying a premium to ensure a better standard of living for cocoa farmers and their families.

We’ve seen firsthand how our partnerships empower communities, improving their farming practices and livelihoods; solar power to help dry the cocoa, water pumps, and even judging local chocolate-making competitions.

Let's be good neighbours

In 2021, we launched our Grower Partner Initiative to increase our ability to source from our Pacific neighbours. This led to our first single-origin Vanuatu bar and opened up a world of exceptional chocolate in our backyard.

The success of this programme, along with improving infrastructure across the Pacific, allowed us to take the bold step in 2024 to source the majority of our beans from Pacific growers.

We craft honest chocolate

Being transparent is important to us. It not only shows you why our chocolate tastes good, it shows you how it does good. And we hope it encourages others in our industry to do better.

Through our direct sourcing relationships, we publish the farmgate price - the exact amount we pay for our beans - so you can see the impact of our work firsthand.

Our Bean-to-Bar Process

There is an easy way to make chocolate: melt down industrially-produced, ready-made chocolate to make bars.

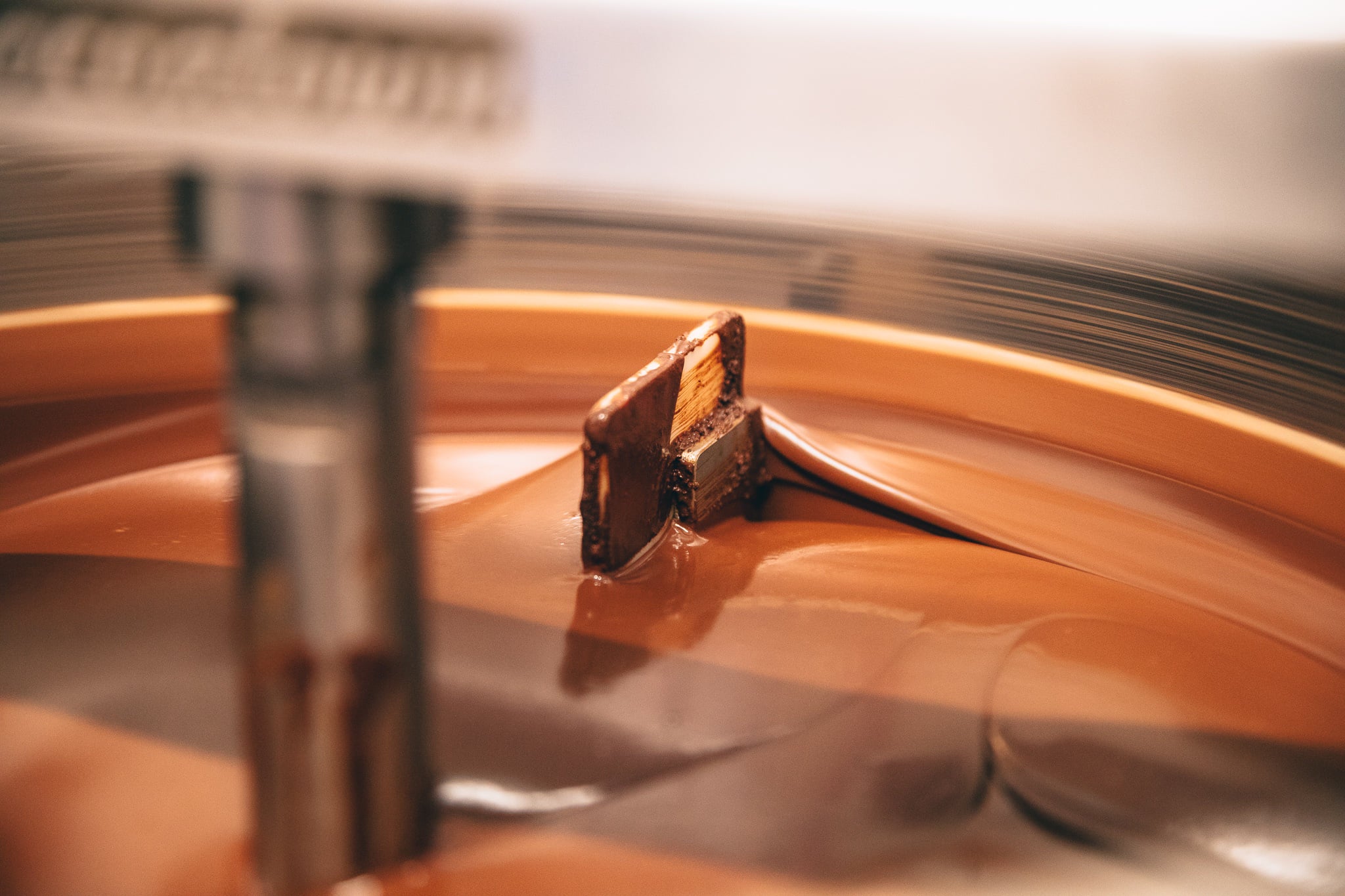

Then there is the WCF way: start from scratch at the source of all great chocolate, the humble cacao bean.

Here are some of our steps for making extraordinary bean-to-bar chocolate: